I increase here some engineproject pictures. I have built some flathead engines for own use and to my customers. During last 5-7 years pediod also built one Ford 347cid engine, two 383cid SB Chevy engine and one 506cid BB Chevy engine.

Here I put only FLathead engine pics. Later I increase text and building pics.... and engine specs too.

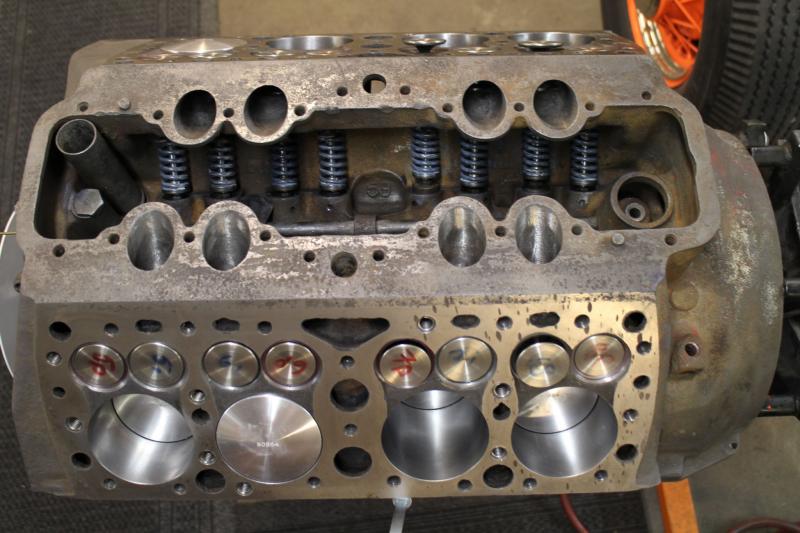

1. FORD FLATHEAD 284CID SUPERCHARGER -ENGINE. ITALMECCANICA 4000/2

-59A block

-bored big + merc 53 forged crank. journals grinded to 2"

-H-beam rods 7" + Ross forged pistons + total seal rings

-Potvin 400 cam + hollow adjust lifters + Isky g185 springs + Manley Pro Flo 1.50/1.60 valves

-ported IN and EX runners

-All short block internal balanced

-Navarro 8.25 heads

-2row truck pumps + homemade pulleys crank, supercharger

-italmeccanica 4000/2 supercharger + 2 x 48 stromberg (big bore)

-harman collins magneto

-Auliz racing oilpan with extra capasity

-Weber alum. flywheel + 9.5" new clutch

-+280hp +380N

Engine looks like this one year. Before made engins swap to Cabriolet I made 2row crank pulley and finished supercharger pulley.

Magneto coil was come back home from "magnetoman" who recoiled it.

Here all pulleys are firrst time on their places even Idler pulley.

Its biggest job to make runners bigger. Its big part castiron need to remove. I use in my engines lightweight ProFlo Manley valves.

In 1.60" and Ex. 1.50". This block was very bad condition. over 60% of all threads need to block off and and make new thread. Helicoil was not good choise.

Ready runners and valveseats.

Eagle 7" h-beam rods with small 2" journal (Original 2.199"). Pontiac bearings are used in this case.

Pistons, pins and spiralocks installed and extralong piston rings are grineded to right dimension.

All shortblock balanced in Helsinki. Big bore forged pistons are more lightweight than original stuff.

One piston installed for test.

Own production oilpan polished. It takes approx. 8hours to polish it.

Cam has been installed and checked installation decreees.

I shim new G-185 Iskenderian springs to get enough seat pressure. Shims from 0.5mm to 1.00mm

Valves touch smoothly champer wall, so I need to fix heads....

Potvin 400" lift cam needs enough free space to open. This engine has 8.00-8.00:1 compression ratio before supercharger boost.

Gives good "horse kick" when drag on street....

Idler pulley ready.

Harman Collings 40´s magneto coil has recoiled. In this pic U just start to put it together. After that most important thing with magnetos:

Timing, timing and once more check that timing is right. There must be many things just right installed to get strong sparks.

2row trck pumps need to rebuilt, because those are not available new ones.

Supercharger just tuned up. All tolerances need to be right or it not gives good boost.

New metric bearings and seals.

Few differennt semiready pulley. Left: that pulley I made to crank, middle: to supercharger, right; old "junk" supercharger pulley.

Crank pulley and pulley hub installed together using very tight installation tolerance (+2/100mm).

I want to lock installation with locking screws from many places.

This is supercharger pulley. two row classic B-belt widht and one 1/2" basic belt width (generator)

Fits good, and sounds "beast".

2. AULIZ -FLATHEAD OILPAN

I didn´t found any racing oilpan to pre 1948 Ford flathead engines (21bolt, 24bolt..). 2015 I decided to made own mould. I found good casting company from Middle-Finland and they made alum. casting. I made jigs for bolt circles etc. This older Flathead oilpan is same time oilpan and bellhousing. All machineryjobs need to made very small tolerances, because bolt holes, rear gasket, tranny mounting surface....

3. 255CID FLATHEAD

I made this engine 2017 and sold it to Helsinki.

4. 1953 Mercury 255cid , customer´s engine.

This engine rebuilding I have done 2019 january. I bored engine to 040 oversize, changed all In. valves to Manley SS and used engines original SS ex. valves. New cast pistons+rings. I made all valve seat jobs, changed cam to Winfield SU1A, johnson hollow adjust. lifters. I found good used retainers and valve quides. Customer were bought old fenton intake which I used and rebuilt his old Stromberg-97 carbs. New bearings, oilpump I used original, because it was like new.

Biggest job is to grind all valves and made new valve seats. Many times 1st generation new leadfree gasolines have worsen valves and valveseats. Valve seats is most important thing in all engines. Overleak to "downstairs" can be rather much and still engine is running good, but if valves are leak, it´s "game over".

5. Own 284cid big bore & 4" stroke Flathead built 2/2019.

I have so much engine parts on stock, so I decided to built one engine for own use or for sale. I used this engien 59A very good condition block which I blueprinted, bored to 3.342", made intake runners bigger etc. I used 1.60" pro flow Manley SS valves and made valve seats approx. 3.5-4.0mm bigger than original. Ex. valves I used 1.50" pro flo manley. Cam is Winfield SU, old original grinding. Lifters new Johnson style adjustable, mercury springs, new valve locks, retainers.... Crank I grinded to 020 undersize, new M-19 oilpump, NOS schiefer alum. flywheel with 10" cluch. Navarro new heads, Auliz oilpan and Mercury pinkrods with Ross forged lightweight pistons. Intake is new Edelbrock slingshot + 2 x new 94 carb. Distributor will be new Stromberg 12v elecrical.

8000e - 8500e if You are interested in. I have also extra parts like ceramic coated headers, Auliz s-curve lower radiator hoses, 12V powermaster alternator....

AULIS